Three boosters of the golden biocomposites era

Anyone who dares to read Peter Zeihan’s current bestseller “The end of the world is just the beginning” immediately understands the value of renewable, local raw materials and thus biocomposites. Peter Zeihan convincingly demonstrates that global logistics chains are crumbling at an accelerated rate. International transportation is becoming riskier, more expensive and raw materials are becoming scarcer and more valuable. In his view, the future is for countries that bet on local and renewable raw materials. But the breakthrough for biocomposites and thus biobased construction rests on more pillars. The three drivers for the golden age of biocomposites put together and why it is better to get ahead in the building industry.

The Big Recalibration, driver for biocomposites

In the United States, the “Big Recalibration” is in full swing. That term is used for the trend in which American business is bringing its production and R&D back to the US. Formerly extinct industrial areas are coming back to life and many Americans are moving from the big cities to these economic growth areas. We are also seeing this trend in the Netherlands, here it is called “reshoring”. The faltering international logistics chains reinforce this trend, and circular local commodities are getting more and more attention. After all, you eliminate risky, long supply chains. Biocomposites can be produced 100% locally and with local raw materials, and timely delivery is therefore once again assured. A huge incentive for bio-based building.

Lower cost bioplastics and raw materials

Biocomposites are also becoming cheaper and cheaper. For starters, producers are now beginning to produce composites on a large scale, and this is reducing unit costs. In addition, raw materials for biocomposites are often already cheaper than known building materials such as concrete, steel, wood and aluminum. Examples of these new raw materials are roadside grass, reeds, residual streams from agriculture, but also Recell’s tertiary cellulose from residual streams. The difference in cost price between internationally sourced and non-circular raw materials and the new raw materials such as bioplastics is only increasing.

ECI ‘through the roof’ by bio-based building

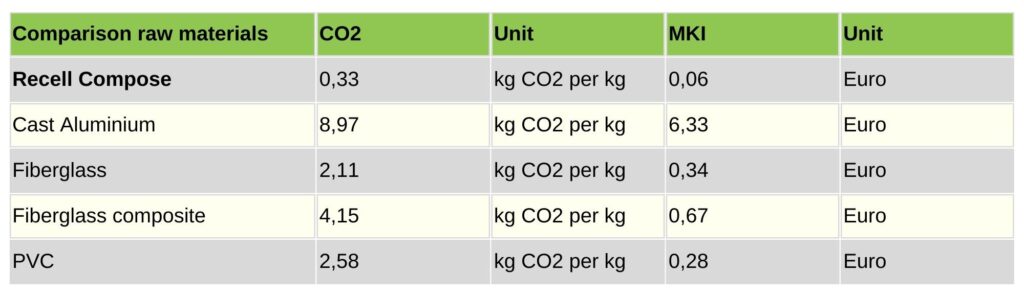

Driven by European ambitions, the Netherlands will further tighten the MPG (i.e. the environmental performance of buildings). Biocomposites by definition have a lower ECI than alternative building materials due to their raw materials. This makes this new generation of building materials a welcome ally for architects and manufacturers. Consequently, the construction industry is developing a preference for biocomposites. This review compares the ECI’s of building materials and Recell’s tertiary cellulose for biocomposites, and this comparison says a lot. Especially when you know that the latest generation of biocomposites can consist of 50 to 65% Recell Compose.

Caption: If you replace fiberglass composite with Recell Compose (with a 50% share), for example, you reduce the MKI of half of the building material 11 times. Source: National Environmental Database (NMD)

Innovative ecosystem biobased building

On top of that, biocomposites are developing rapidly. We have insight into this, because Recell is closely involved in the development of biocomposites through our customers and in all kinds of partnerships as a raw material supplier. For example, we develop together with NPSP, which supplies fantastic building materials. Another example is Omlab, which develops 3D printing materials and 3D printing applications. Both companies are finding that the tailwind for biocomposites has picked up, but of course another explanation for the golden age can be found in the unique material properties of biocomposites. But more on that in a future post.

Want to know more?

Do you want to know more about Recell Compose or about Recell® in general? Leave a message on our contact page!